-

×

F144058M-PIPETMAN G P200G, 20-200 µL, Metal Ejector-Gilson

2 × $457.00

F144058M-PIPETMAN G P200G, 20-200 µL, Metal Ejector-Gilson

2 × $457.00 -

×

88870116, Digital and Touchscreen Dry Bath Accessories Thermo Scientific- 15mL Flat-Bottom Tube Block

2 × $164.00

88870116, Digital and Touchscreen Dry Bath Accessories Thermo Scientific- 15mL Flat-Bottom Tube Block

2 × $164.00 -

×

9010-0217 FED 400 UL Heating Chamber With Forced Convection Binder

1 × $7,811.00

9010-0217 FED 400 UL Heating Chamber With Forced Convection Binder

1 × $7,811.00 -

×

711211010-FreeZone 12 Liter -84C Console Freeze Dryer- Labconco

1 × $27,849.55

711211010-FreeZone 12 Liter -84C Console Freeze Dryer- Labconco

1 × $27,849.55 -

×

701212030- FreeZone 12 Liter -50C Console Freeze Dryer- Labconco

1 × $25,038.95

701212030- FreeZone 12 Liter -50C Console Freeze Dryer- Labconco

1 × $25,038.95 -

×

EZ-190F - Auto Flow Vaporizer Machine - E-Z Systems

1 × $5,202.00

EZ-190F - Auto Flow Vaporizer Machine - E-Z Systems

1 × $5,202.00 -

×

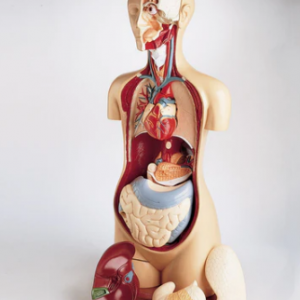

0708-00 Basic Knowbody Teaching Torso - Denoyer-Geppert

1 × $1,691.00

0708-00 Basic Knowbody Teaching Torso - Denoyer-Geppert

1 × $1,691.00 -

×

A-105171 Half Disarticulated Human Skeleton Axis Scientific

1 × $215.60

A-105171 Half Disarticulated Human Skeleton Axis Scientific

1 × $215.60 -

×

RE801C-W- Rotary EvaporatorRE801C-W - Yamato

1 × $7,464.60

RE801C-W- Rotary EvaporatorRE801C-W - Yamato

1 × $7,464.60 -

×

19-050A - Bead Ruptor 12- Omni International

1 × $5,884.00

19-050A - Bead Ruptor 12- Omni International

1 × $5,884.00 -

×

4330SL Siliconized Polypropylene 0.5ml Flat Top Microcentrifuge Tube (Pack Of 500) Bio Plas

1 × $30.00

4330SL Siliconized Polypropylene 0.5ml Flat Top Microcentrifuge Tube (Pack Of 500) Bio Plas

1 × $30.00 -

×

06-209-15 - 15 Ml Omni Prep Tube Holder- Omni International

1 × $124.00

06-209-15 - 15 Ml Omni Prep Tube Holder- Omni International

1 × $124.00 -

×

19-353-0150 - Omni Bead Ruptor 12 Microtube Adapter, 4-Pack- Omni International

1 × $712.00

19-353-0150 - Omni Bead Ruptor 12 Microtube Adapter, 4-Pack- Omni International

1 × $712.00 -

×

RE301A-O - Rotary evaporator, Glass "A", Oil Bath- Yamato

1 × $3,685.00

RE301A-O - Rotary evaporator, Glass "A", Oil Bath- Yamato

1 × $3,685.00 -

×

A-105179, 22-Part Disarticulated Life-Size Human Skull Axis Scientific

1 × $319.00

A-105179, 22-Part Disarticulated Life-Size Human Skull Axis Scientific

1 × $319.00 -

×

NH300, Portable Colorimeter 3nh

1 × $1,420.00

NH300, Portable Colorimeter 3nh

1 × $1,420.00 -

×

A-105170 Miniature Painted Human Skeleton Axis Scientific

1 × $243.10

A-105170 Miniature Painted Human Skeleton Axis Scientific

1 × $243.10

Subtotal: $88,931.80