| Model |

DKM300C

DKM310C |

DKM400C

DKM410C |

DKM600C

DKM610C |

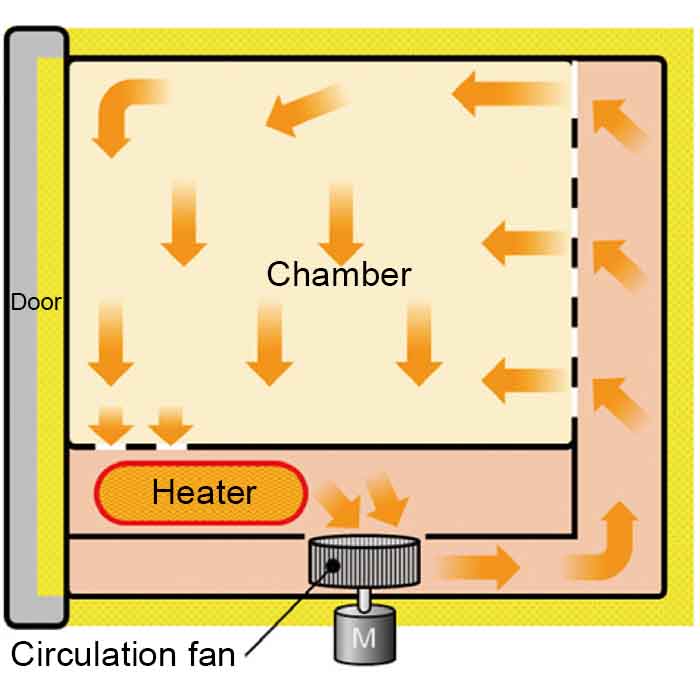

| Circulation Method |

Forced air circulation |

| Operating Temperature Range |

Room temp. +10~260°C |

| Temp. Control Accuracy |

±1°C (at 210°C) |

| Temp. Distribution Accuracy |

±2.5°C (at 210°C) |

| Max. Temp. Reaching Time |

~90min (at room temp. +10°C~260°C) |

| Interior Material |

Stainless steel |

| Exterior Material |

Cold rolled steel plate with melamine resin baking finish |

| Heat Insulating Material |

Glass wool |

| Heater |

SUS pipe heater / 0.8kW |

SUS pipe heater / 1.2kW |

SUS pipe heater / 1.34kW |

| Fan Type / Motor |

Scirocco fan / Condenser type motor 10W |

| Cable Port |

30 mm l.D.×1 pc. (right side) |

| Exhaust Port |

30 mm l.D.×2 pcs. (the top) |

| Temp. Controller |

PlD control by microprocessor |

| Temp. Setting Method |

Operation menu key and digital setting by ▲/▼ key |

| Temp Display Method |

Measurement temp. : Digital display by green LED / Setting temp. : Digital display by red LED |

| Timer |

1 min. to 99 Hrs. 59 min. and 100 Hrs. to 999 Hrs. 50 min. (with time wait function) |

| Operation Functions |

Fixed temperature operation, Quick Auto-stop, Auto start, Auto stop |

| Additional Functions |

Calibration off-set function, Key lock, Uninterruptible power for memory |

| Heater Circuit Control |

SSR control |

| Sensor |

K-thermocouple |

| Safety Device |

Self diagnostic functions (Sensor trouble detection, Memory error, Measured temperature lower limit error, Measured temperature error), Auto overheat prevention, Independent overheat prevention. |

| Internal Dimensions W×D×H |

300×300×300mm |

450×450×450mm |

600×500×500mm |

| External Dimensions W×D×H |

410×451×670mm |

560×601×820mm |

710×651×870mm |

| Internal Capacity |

27L |

90L |

150L |

| Shelf Plate With Standard Load |

15kg/piece |

| Shelf Rest Step Number |

6 steps |

9 steps |

12 steps |

| Shelf Rest Pitch |

35mm |

| Power Source 50/60Hz |

AC115V 7.5A (with plug)

AC220V 4.5A (no plug, round terminal) |

AC115V 11A (with plug)

AC220V 6.5A (no plug, round terminal) |

AC115V 12A (with plug)

AC220V 7A (no plug, round terminal) |

| Weight |

~35kg |

~50kg |

~65kg |

| Shelf Plate / Bracket |

Stainless steel 2 pcs. / 4 pcs. |

MK161 Shaker Rtr Ellpt Recp 20-200rpm 115V/220V Yamato

1 × $2,488.20

MK161 Shaker Rtr Ellpt Recp 20-200rpm 115V/220V Yamato

1 × $2,488.20  0094 Orange Polypropylene Reversible 1.5ml And 2.0ml Microcentrifuge Tube Rack, 96 Places (Pack Of 5) Bio Plas

1 × $31.00

0094 Orange Polypropylene Reversible 1.5ml And 2.0ml Microcentrifuge Tube Rack, 96 Places (Pack Of 5) Bio Plas

1 × $31.00