| Model |

DF412 |

DF612 |

DH412 |

DH612 |

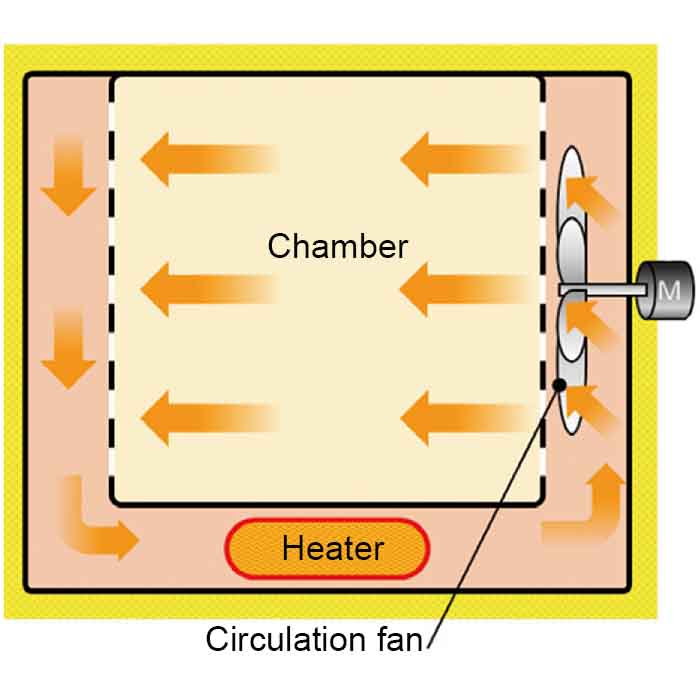

| System |

Forced air circulation and ventilation |

| Operating Temp. Range*¹ |

Room temp. +15~260°C |

Room temp. +15~360°C |

| Temp. Adjustment Accuracy*¹ |

± 0.1°C (at 260°C) |

± 0.2°C (at 360°C) |

| Temp. Distribution Accuracy*¹ |

± 1.5°C (at 260°C) |

± 2.5°C (at 360°C) |

| Max. Temp. Reaching Time*¹ |

~40 min. (reaches 260°C when setting at 270°C) |

~50 min. (reaches 360°C when setting at 370°C) |

| Temp. Control System |

PlD Z control |

| Temp. Setting Method |

Digital setting by ▲/▼ key |

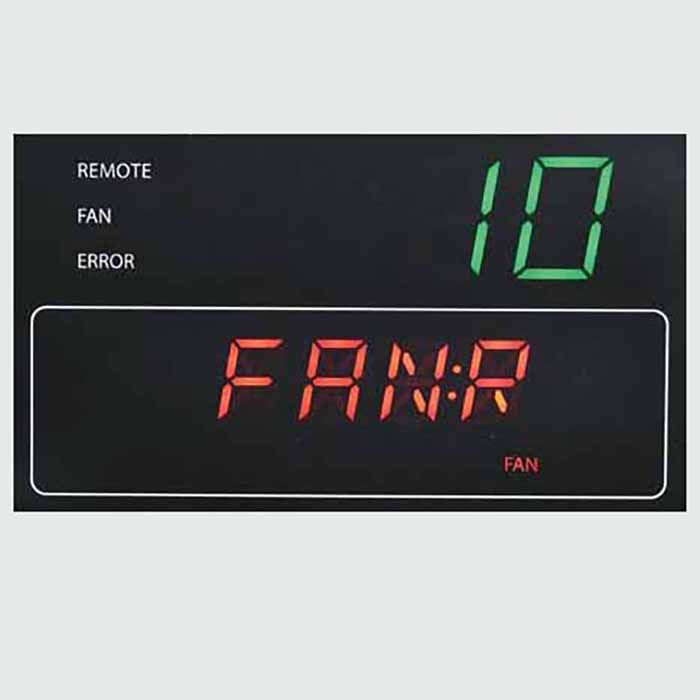

| Temp. Display Method |

Setting temp. display: Digital display by 5-digit orange LED (resolution: 1°C) Temp. display: Digital display by 4-digit green LED (resolution: 1°C) |

| Other Indication |

LED indicates temperature patterns for heating/stabilizing/cooling |

| Timer Display Range |

Fixed value operation for 1 min. to 99 hrs. 59 mins. 24 hr time system: clock operation |

| Operation Functions |

Fixed temperature, Auto start, Auto stop, Program operation: up to 99 steps, 99 patterns, repeat operation function |

| Additional Functions |

Variable air flow function, power on time and timer accumulation monitor (up to 65535 hrs), calibration offset, power consumption display, total CO₂ emissions and heat operation output, power failure recovery mode, setting data backup and recovery |

| Sensor |

K thermocouple (double sensor) |

| Heater Insulator |

SUS pipe heater with fan |

| Heater Capacity |

2.1 kW |

3.0 kW |

2.7 kW |

3.75 kW |

| Blower Fan (Motor) |

Axial fan (capacitor type motor 20W) |

| Cable Port |

I.D. 33 mm x 1 pc. (rear) |

| Interior / Exterior Material |

Stainless steel/ Chrome-free electro-galvanized steel sheet metal, chemical-proof baked on finish |

| Door |

Single swing (left side) |

| Exhaust Port |

Automatic exhaust damper I.D. 80 mm (rear panel) |

| Heat Insulator |

Glass wool |

| Heater Circuit Control |

Triac with zero-crossing method |

| Earth Leakage Breaker |

15A |

20A |

20A |

30A |

| Leak current/short circuit / Over-current protection, rated current sensitivity 30mA |

| Safety Device |

Self-diagnostic functions (temp. sensor error, TRIAC short circuit, heater disconnection, SSR short-circuit, fan motor failure, main relay contact damage and overheating), key lock function, door switch (door open, fan motor and heater circuit OFF / door close: fan motor and heater circuit ON), independent overheat prevention (temp. setting range: 0~300°C for DF and 0~400°C for DH) |

| Internal Dimensions*² W×D×H |

450×450×450 mm |

600×600×600 mm |

450×450×450 mm |

600×600×600 mm |

| External Dimensions*² W×D×H |

1050×630×850 mm |

1200×780×1000 mm |

1050×630×850 mm |

1200×780×1000 mm |

| Internal Capacity |

91L |

216L |

91L |

216L |

| Shelf Max. Load |

~30kg / pc. |

| Shelf Support Qty. / Pitch |

9 steps / 45mm |

9 steps / 60mm |

9 steps / 45mm |

9 steps / 60mm |

| Power Source 50/60 Hz Single Phase |

AC220V 12.5A (no plug, round terminal) |

AC220V 17.5A (no plug, round terminal) |

AC220V 15.5A (no plug, round terminal) |

AC220V 17.5A (no plug, round terminal) |

| Weight |

~112 kg |

~156 kg |

~112 kg |

~156 kg |

| Shelf / Bracket |

2 pcs / 4 pcs |

3 pcs / 6 pcs |

2 pcs / 4 pcs |

3 pcs / 6 pcs |

0090 Natural Polypropylene Reversible 1.5ml And 2.0ml Microcentrifuge Tube Rack, 96 Places (Pack Of 5) Bio Plas

1 × $28.00

0090 Natural Polypropylene Reversible 1.5ml And 2.0ml Microcentrifuge Tube Rack, 96 Places (Pack Of 5) Bio Plas

1 × $28.00  0097 Lavender Polypropylene Reversible 1.5ml And 2.0ml Microcentrifuge Tube Rack, 96 Places (Pack Of 5) Bio Plas

1 × $31.00

0097 Lavender Polypropylene Reversible 1.5ml And 2.0ml Microcentrifuge Tube Rack, 96 Places (Pack Of 5) Bio Plas

1 × $31.00  0096F WELL MICROCENTRIFUGE TUBE RACK, FLUORESCENT YELLOW, 5/PK Bio Plas

1 × $33.00

0096F WELL MICROCENTRIFUGE TUBE RACK, FLUORESCENT YELLOW, 5/PK Bio Plas

1 × $33.00  911015119999 D2012 Plus High Speed Personal Micro-Centrifuge Scilogex

6 × $935.00

911015119999 D2012 Plus High Speed Personal Micro-Centrifuge Scilogex

6 × $935.00  MYA 2.4Y- Micro Balance, 2.1 g x 0.001 mg - Radwag

2 × $12,100.00

MYA 2.4Y- Micro Balance, 2.1 g x 0.001 mg - Radwag

2 × $12,100.00  SMO28G-2- OVEN FORCED AIR 27.5 CF 230V CERAKOTE - SHELLAB

1 × $7,360.00

SMO28G-2- OVEN FORCED AIR 27.5 CF 230V CERAKOTE - SHELLAB

1 × $7,360.00